Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers

manufacturer, supplier, exporter in Mumbai, India

Table of Contents

Description of Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers

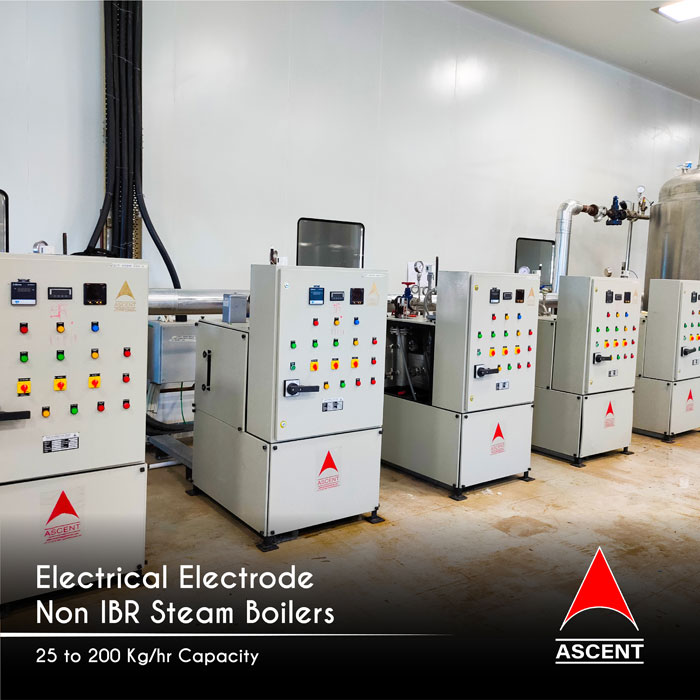

Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers are compact, efficient, and reliable industrial boilers used in an extensive range of industries. These electrical steam boilers are designed to generate steam using electricity and electrodes, making them ideal for applications where fuel availability is limited or where emissions need to be minimized. With a capacity of 25 kg/hr, these Non IBR boilers can produce enough steam to meet the needs of small-scale industrial processes and laboratory applications.

ASCENT MACHINERIES & ENGG. SERVICES is likely to have a track record of providing quality industrial boilers to various industries such as food processing, chemical, pharmaceutical, and textile industries. The electrical/electrode design of these electrode steam boilers allows for precise temperature control and quick response times. Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers offer a reliable and efficient solution for small-scale steam generation needs in a wide range of industries.

Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers Specifications

The non ibr boiler capacity along with other specifications are mentioned below: –

| Company Name | ASCENT MACHINERIES & ENGG. SERVICES |

| Product Name | Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers |

| Model No. | AET – 18 |

| Evaporation Capacity | 25 Kgs/Hr |

| Heater | 18 Kw |

| Pump | 0.5 hp |

| Dimensions – mm | |

| Length | 1500 |

| Width | 500 |

| Height | 1200 |

| Dry Weights Approx. | 300 Kgs |

Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers Features

- Electrical or electrode-based heating system – The steam boilers use either electrical energy or electrodes to heat the water and generate steam.

- Non IBR design – Electrical steam boilers have a non-IBR (Indian Boiler Regulation) design, which means that they do not require a separate boiler inspector to operate them.

- High efficiency – Electrode steam boilers have high efficiency, which means that they use less energy to produce the same amount of steam compared to traditional boilers.

- Compact design – The Non IBR steam boilers have a compact design, which makes them suitable for use in small spaces.

- Easy to operate – Electrical/Electrode Steam Boilers are easy to operate and maintain, making them suitable for use in a variety of industries.

- Safety features – Provided with safety features such as pressure gauges, safety valves, and low water level cut-off switches to ensure safe and reliable operation.

- Corrosion resistant – Electrical Non IBR Steam Boilers are made of corrosion-resistant materials, which ensures their longevity and reliability.

- Automatic controls – Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers have automatic controls to regulate the temperature and pressure, ensuring optimal performance and efficiency.

Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers Applications

- Food processing: – Electrical steam boilers are used for cooking, baking, and other food processing operations that require steam.

- Sterilization: – Electrode steam boilers are ideal for boiling, blanching, or sterilizing food products.

- Dairy products: – Non IBR steam boilers are commonly used in the production of dairy products such as milk and cheese.

- Processing: – Steam boiler is used in cooking and processing of fruits and vegetables.

- Beverages: – Electrical Non IBR Steam Boilers are used in the production of beverages such as beer and wine.

- Cooking: – Electrical/Electrode 25 kg/hr Capacity Non IBR Steam Boilers provides a reliable source of steam for cooking, sterilizing, and other essential processes in the food industry.