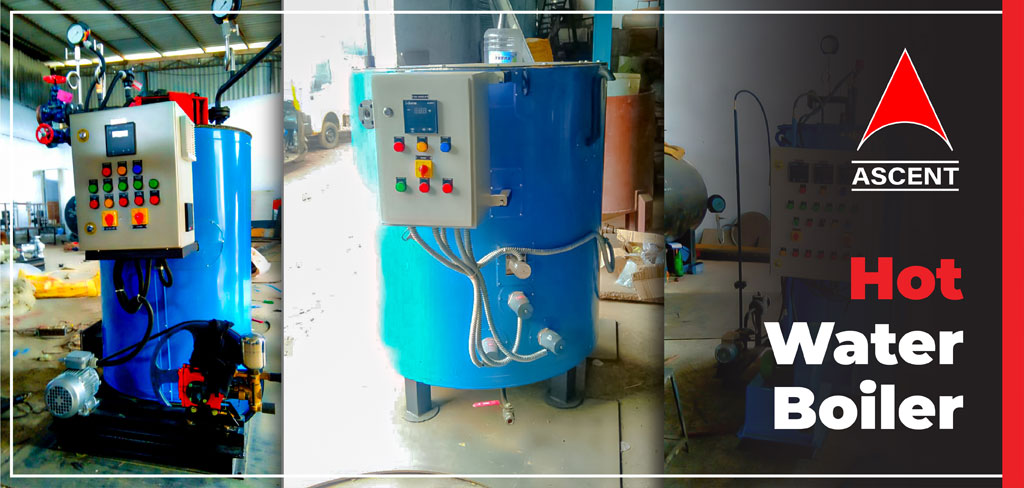

Hot Water Boiler/Hot Water generator

Table of Contents

Share

Quick Enquiry Form

Introduction to Hot Water Boiler / Hot Water generator

A hot water boiler or hot water system is a heating system that uses water or oil as the heat transfer medium to provide warmth to homes, buildings, or industrial processes. These systems work by heating the water or oil in a tank or reservoir and then circulating it through pipes or ducts to provide heat to various points of use.

Hot water boiler industrial is highly efficient and reliable, providing consistent heat to homes, buildings, and industrial processes. They offer several advantages over other heating systems, such as faster heat distribution, lower operating costs, and easier maintenance.

Hot Water Boiler Heating Systems are typically used for residential and commercial heating applications, such as space heating and water heating. They are often used in conjunction with radiators, baseboard heaters, or in-floor heating systems.

Hot water systems, on the other hand, are commonly used in industrial processes, such as chemical and pharmaceutical manufacturing, food processing, and asphalt production. They offer precise temperature control, ensuring that the process materials are heated to the exact temperature required for efficient operation.

Overall, industrial hot water boiler systems are highly effective heating solutions for a wide range of applications. They are energy-efficient, reliable, and easy to maintain, making them a popular choice for homeowners, business owners, and industrial operators alike.

Hot Water Boiler Price

| Electrical Hot Water Boiler | |

| Model No. | AHE – 4.5 |

| Capacity – Kcal/Hr | 3870 |

| Temp. Max – Deg C | 90 |

| Delta T – Deg C | 10 |

| Water Flow – lph | 387 |

| Heater – kwh | 4.5 |

| Pump -hp | 0.5 |

| Dimensions mm | |

| Length | 800 |

| Width | 400 |

| Height | 1200 |

| Dry Weight Approx. – Kgs. | 250 |

| Price | |

How Does a Hot Water Boiler Work?

An industrial hot water boiler is a device that uses fuel or electricity to heat water and produce hot water for industrial processes and applications. The working principle of a hot water boiler involves the transfer of heat energy from the fuel or electricity source to the water, which is then circulated through a piping system to the application.

There are different types of industrial hot water boilers, including electric hot water boiler, gas hot water boiler, oil hot water boiler and solid fuel boiler. However, they all share the same basic working principle.

The fuel or electricity source heats the water in the boiler’s tank, which can vary in size depending on the application. The heat transfer occurs through a heat exchanger, which is a metal surface that comes into contact with the water.

The heated water is then circulated through a piping system to the application, such as a manufacturing process, building heating, or cleaning application. The piping system may be equipped with pumps to help circulate the water and maintain a consistent temperature.

To ensure safe and efficient operation, hot water boiler systems also include safety features such as pressure and temperature sensors, safety valves, and control systems. These features help regulate the boiler’s temperature and pressure, preventing any potential hazards or damage to the system.

In summary, the working principle of an industrial boiler involves heating water using a fuel or electricity source, transferring the heat energy to the water through a heat exchanger, and circulating the heated water through a piping system to the application.

Hot Water Boiler Design & Construction

Hot water boilers are widely used in various industries for heating and producing hot water for a wide range of applications. The design and construction of industrial hot water boilers is critical to their efficiency, safety, and reliability.

- Boiler Construction: Hot water generators are typically constructed of steel or cast iron. Steel boilers are lighter in weight and more affordable, while cast iron boilers are more durable and resistant to corrosion. The boiler’s shell is typically insulated to reduce heat loss and improve energy efficiency.

- Boiler Combustion: The fuel used for a hot water boiler heating system can be oil, gas, or solid fuel, depending on the application. The combustion chamber is designed to burn the fuel efficiently and minimize emissions. The burner is mounted on the front of the boiler and may be equipped with a fan to ensure efficient combustion.

- Heat Exchanger: The heat exchanger is the most critical component of the hot water boiler. It is responsible for transferring heat from the combustion gases to the water. In fire-tube boilers, the heat exchanger is a series of tubes that run through the boiler’s shell. In water-tube boilers, the heat exchanger is a series of tubes that run through the water-filled chamber.

- Piping System: The hot water boiler’s piping system is designed to distribute hot water to the application and return the cooler water to the boiler for reheating. The piping system may be equipped with pumps to ensure proper flow and pressure. It is important to ensure the piping system is properly insulated to reduce heat loss and improve energy efficiency.

- Controls: The hot water boiler’s controls are critical for safe and efficient operation. The controls include a thermostat to regulate the water temperature, a pressure relief valve to prevent overpressure, and a water level control to ensure proper water level in the boiler.

In conclusion, hot water boiler design and construction are critical to their efficiency, safety, and reliability. The boiler’s configuration, construction, combustion, heat exchanger, piping system, and controls are all key components that must be designed and constructed properly to ensure optimal performance.

Applications of Hot Water Boiler

Hot water boilers or hot water generators are widely used in various industries for producing hot water for a wide range of applications. Some of them are given below:

- Building Heating: Hot water boilers are commonly used for heating buildings, including homes, offices, hospitals, and schools. The hot water is circulated through a piping system and radiators or underfloor heating systems to provide heat to the building.

- Industrial Processes: Industrial Hot water boilers are used in various industrial processes that require hot water for heating, cleaning, and other applications. Examples include food processing, chemical manufacturing, and textile production.

- Domestic Hot Water: Hot water systems are used for producing domestic hot water for homes and other residential buildings. The hot water is stored in a tank and distributed to taps and showers for use.

- Greenhouse Heating: Hot water generators are commonly used for heating greenhouses and other agricultural facilities. The hot water is circulated through pipes or tubes to provide heat to the plants and maintain the desired temperature and humidity levels.

- Laundry and Cleaning: Industrial boilers are used in laundries and cleaning facilities for producing hot water for washing and cleaning applications. The hot water is used for washing clothes, bedding, and other textiles, as well as cleaning floors, walls, and equipment.

- Brewing and Distilling: Hot water boiler systems are used in brewing and distilling facilities for producing hot water for brewing and distilling processes. The hot water is used for mashing, lautering, and sparging in brewing, and for mashing and distilling in distilling.

In conclusion, hot water boilers or hot water generators are used in a wide range of applications, including building heating, industrial processes, domestic hot water, greenhouse heating, laundry and cleaning, and brewing and distilling. The specific application will determine the type and size of the hot water boiler required.