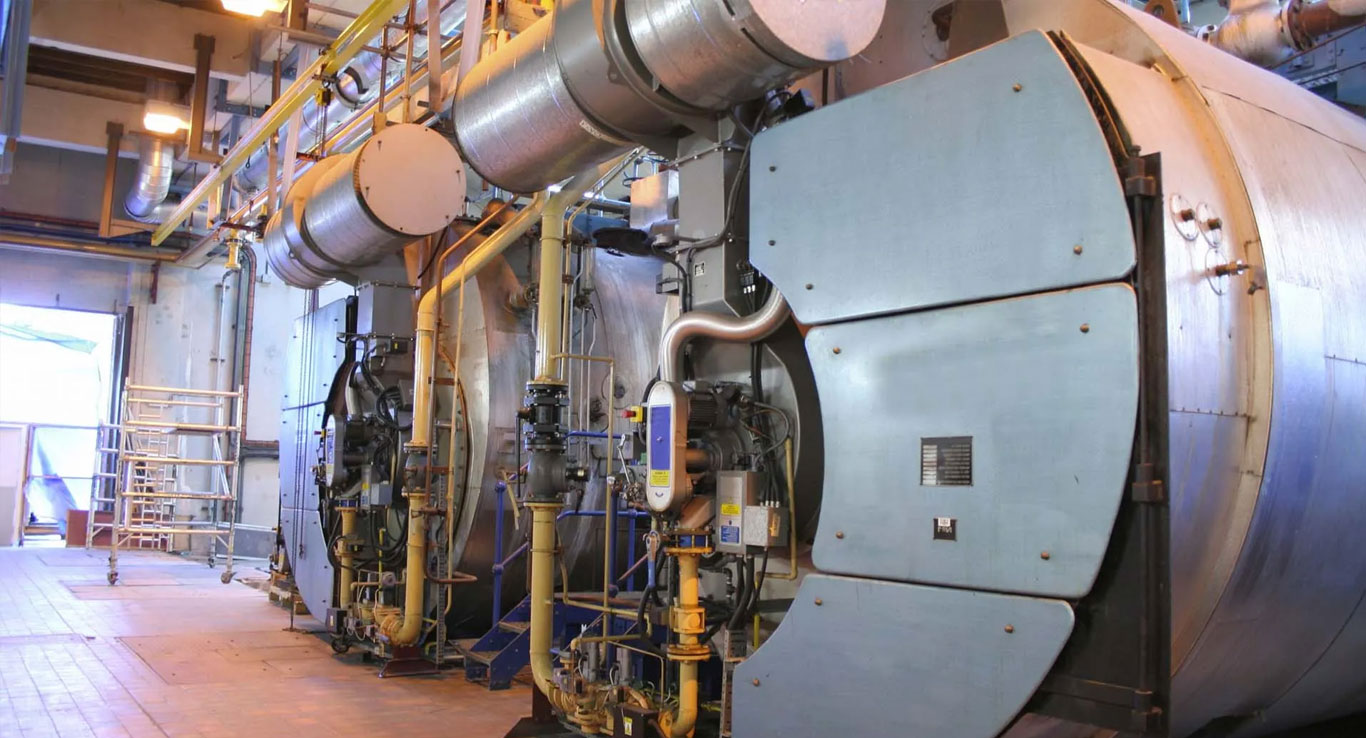

Introduction to Industrial Steam boilers

Industrial Steam boilers are essential for the smooth functioning of numerous manufacturing industries, as they provide the necessary steam for various process operations. The use of steam is integral for purposes such as heating, drying, processing, sterilizing, and more. The textile industry is a prime example of an industry that relies heavily on steam for its major processing stages. Textile production is an ancient industry that has undergone various changes and advancements over the centuries to improve its processing efficiency.

The manufacturing process of textiles involves several stages that convert raw fabric into a finished garment. These stages include spinning, weaving, knitting, dyeing, printing, finishing, and packaging. Steam plays a critical role in many of these stages. For instance, in spinning, steam is used to heat and humidity the air to maintain the required humidity levels to avoid fiber breakage. In weaving and knitting, steam is used for fabric-setting processes.

In dyeing, steam is used to heat and maintain the temperature of the dyeing machines. Steam is also used in printing processes to set the ink and ensure that it adheres to the fabric properly. In finishing processes, steam is used to remove wrinkles and shrinkage from fabrics. Moreover, steam is used in the packaging process to sterilize the finished garments, ensuring that they are free from any microbes that could cause damage during storage or transportation.

Let’s take a closer look at these stages and their respective uses of steam.

The Various Stages of Textile Manufacturing

Yarn Manufacturing or Spinning: The first stage in the textile manufacturing process involves the conversion of raw materials or fibers, such as cotton or man-made fibers like synthetic or nylon, into yarn for knitting, weaving, or crocheting. The raw materials are carefully sorted and cleaned before being processed into the final yarn or thread.

Fabric Manufacturing or Weaving: The next stage of fabric manufacturing involves the transportation of yarn from one machine to another to create a length of fabric. This process involves the interlacing of two or more sets of yarn at right angles to each other, creating a woven fabric.

Wet Processing: The fabric wet processing operation includes various processes such as dyeing and finishing. The dyeing process involves the introduction of colours to the fabric, while the finishing process adds chemical properties such as anti-pill, soil release, flame retardant, and more, to enhance the fabric quality. The printing process includes inkjet printing on fabrics, which allows for intricate and detailed designs.

Garment Processing and Finishing: The final process in the textile industry involves designing and sewing the final garments. This is followed by spot removal, ironing, and finishing to give the garments their final look and feel before they are transported to the market. This stage involves a variety of techniques, including embroidery, applique, and embellishments to create unique and stylish garments.

Role of Steam Boilers in Textile Processing

Steam boilers are an essential component in textile processing industries, as many of the major process operations depend on the use of steam or hot water generated from these boilers. To meet the demands of textile processing, it is crucial to select the right steam boiler that can effectively cater to the various stages of textile processing. Here are the primary stages of textile processing that require steam or hot water:

Pre-treatment: The pre-treatment stage is one of the critical stages in the textile process, involving the removal of dirt or impurities from the fabric before the dyeing and printing process. An efficient steam boiler is required to produce clean and pure steam or hot water, making this stage an essential part of the textile manufacturing process.

Dyeing: The dyeing stage involves adding pigments or dyes to the fabric to colour it. Although the dyeing process can occur at any stage, it primarily occurs after the yarn manufacturing or fabric manufacturing stage of the textile process. The transfer of dye to the fabric requires a precise amount of moisture and heat provided by steam. Steam boilers enable the heating of water and steam at the determined temperature required to dye the fabric in an exact colour.

Printing: The printing stage in the textile process is similar to dyeing, except that printing includes patterns or designs on the fabric, while dyeing includes uniform colouring. Depending on the type of fabric, the printing stage uses various methods, with steam boilers being an essential component for providing the precise amount of heat and moisture required for the printing process.

Finishing: The finishing stage of the textile process involves several steps, including the removal of wrinkles from the fabric. A steam boiler is vital for providing steam for ironing purposes, providing excellent finishing for the final product.

Key Considerations for Selecting a Steam Boiler for Textile Processing

Selecting the right steam boiler for textile processing is crucial to ensure efficient and productive operations. Textile processing managers must consider several factors before making a decision on the type of steam boiler to use.

- One critical factor to consider is the boiler’s ability to operate seamlessly with fluctuating demands for steam. Since steam requirements in textile processing operations tend to vary, robust boilers that can handle these changes effectively are necessary. Boilers that can quickly start or shut off are best suited for processing operations. Water tube boilers typically perform better than fire tube boilers when it comes to handling fluctuating loads.

- Fuel efficiency is another essential consideration. Due to the fluctuating demand for steam, textile processing faces the challenge of fuel wastage, which leads to increased costs. Therefore, steam boilers must perform effectively and ensure complete combustion to optimize fuel utilization.

- Ease of maintenance is another crucial factor to consider. Steam boilers in textile processing operations operate throughout the day and require regular maintenance for optimal results. Neglecting boiler maintenance can lead to boiler failure, halting the textile processing operations and resulting in significant losses.

- Finally, calculating the capacity and heating parameters of steam boilers is essential. The capacity of a steam boiler depends on the heating load, which includes heat losses in boiler tubes and pipes. Additionally, determining heating parameters such as temperature and pressure is critical. By considering these factors, textile processing managers can choose the right steam boiler that will deliver optimal efficiency and productivity.

Conclusion

ASCENT MACHINERIES & ENGG. SERVICES is a leading boiler manufacturer with over 26 years of experience and expertise in thermal solutions. Our boilers have been installed in over several countries worldwide, with more than 500 installations to date. We are renowned for manufacturing the preferred steam boiler model in the textile industry, and we have delivered our efficient steam boilers to many textile process and dyeing units.

We cater to 20 process industries worldwide and manufacture steam boilers, thermic fluid heaters, and boiler accessories. We offer a range of boiler services, including boiler automation, steam trap assessment, energy audit, annual boiler maintenance, and more, to ensure hassle-free operations of steam boilers.

For more information about our products and services, please visit our website at https://ascentmes.com/.