Home > Product Range > Industrial Vessels And Storage Tanks

Industrial vessels and storage tanks are robust containers designed to store, mix, or process liquids, gases, or other materials in various industries. These tanks and vessels are engineered to withstand high pressures, extreme temperatures, and corrosive substances, ensuring the safe and efficient handling of materials. Common applications include chemical processing, oil and gas storage, pharmaceuticals, and water treatment.

The working principle varies based on the type and application but generally involves maintaining the desired conditions for the stored or processed material. These systems are critical for operational efficiency and safety in industrial setups.

Ascent Machineries & Engineering Services Ltd., based in Goregaon, Mumbai, India, is a leading manufacturer, supplier, and exporter of industrial vessels and storage tanks. With decades of expertise, we specialize in delivering durable, high-performance solutions tailored to meet diverse industrial needs. Our products are designed to adhere to global standards, ensuring reliability and long service life.

Corrosion-resistant and robust.

Clean energy solutions for industrial heating.

Ideal for corrosive applications.

Economical options for industrial processes.

Resistant to harsh chemicals.

Engineered for safe oil storage

Durable tanks for industrial and commercial use.

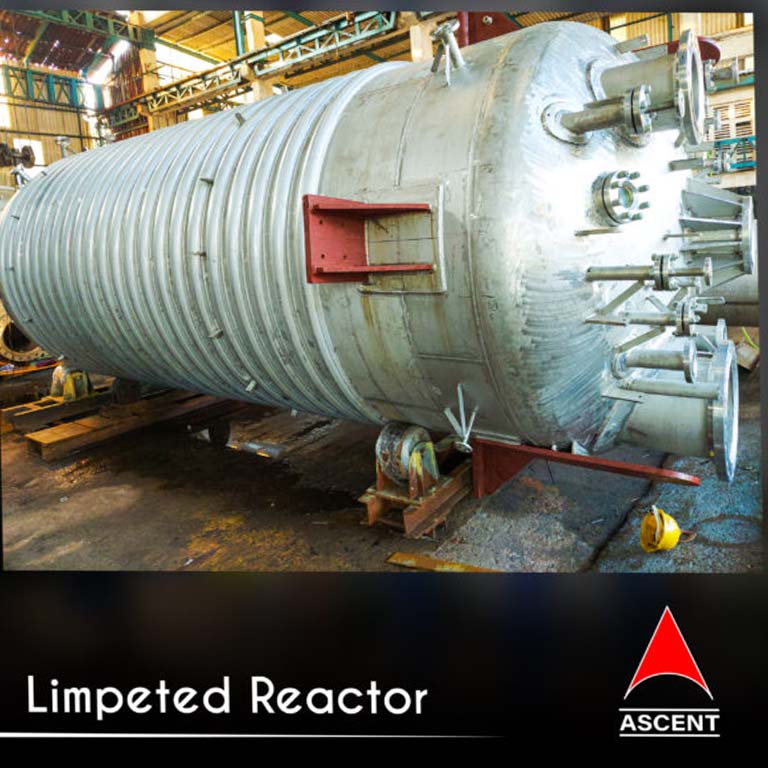

Limpet and jacketed reactors are advanced industrial vessels designed for chemical reactions

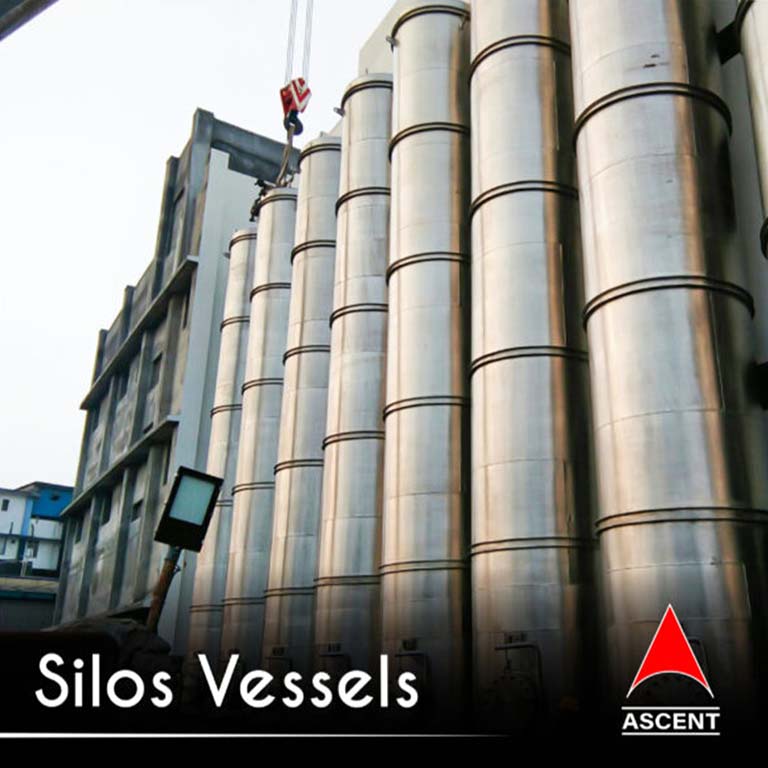

Silo vessels are large storage containers designed to store bulk materials such as grains, cement, chemicals, and minerals.

| Equipment Type | Capacity Range | Material | Operating Pressure | Certifications |

| Pressure Vessels | Up to 500 m³ | Carbon steel, stainless steel | Up to 300 bar | ASME, ISO |

| Reactor Vessels | 1,000 to 20,000 liters | Stainless steel, Hastelloy | Up to 250 bar | CE, GMP |

| Industrial Storage Tanks | 1,000 to 100,000 liters | FRP, stainless steel | Atmospheric pressure | ISO |

| Industrial Tanks | Up to 1,000,000 liters | Carbon steel, stainless steel | Up to 5 bar | ASME, ISO |

| Equipment Type | Initial Cost | Operating Cost | Maintenance Cost | Best Use Case |

| Pressure Vessels | High | Low | Moderate | Storing pressurized gases and liquids |

| Reactor Vessels | High | Moderate | Moderate | Chemical reactions in pharmaceuticals |

| Industrial Storage Tanks | Moderate | Low | Low | Storing water, oil, or chemicals |

| Industrial Tanks | High | Low | Low | Large-scale liquid storage |

We have successfully supplied and exported industrial process equipment to the following countries and cities:

| Country | Cities |

| India | Mumbai, Pune, Chennai, Kolkata |

| UAE | Dubai, Abu Dhabi, Sharjah |

| USA | Houston, Los Angeles, Chicago |

| UK | London, Manchester, Birmingham |

| Germany | Berlin, Frankfurt, Munich |

| Australia | Sydney, Melbourne, Brisbane |

| South Africa | Johannesburg, Cape Town, Durban |

| Singapore | Singapore City |

A storage tank is typically larger and used for bulk storage, while a storage vessel is used for process-specific applications and may operate under pressure.

Operating pressure varies by design. Atmospheric tanks operate at ambient pressure, while pressurized tanks can handle up to 300 bar.

For more details about our industrial process equipment, download our brochure. It includes:

Ensure efficient storage and material handling with high-quality industrial vessels and storage tanks from Ascent Machineries. Contact us today for customized solutions:

ASCENT MACHINERIES & ENGG. SERVICES Shop No. 2, 1st Floor, Nalanda Shopping Center, Station Road, Goregaon West, Mumbai - 400062, Maharashtra, India

+919819063898

sales@ascentmes.com

© 2025 Ascentmes.com. All rights reserved. Designed by Vebiotic Web Solutions Marketing by Adinads