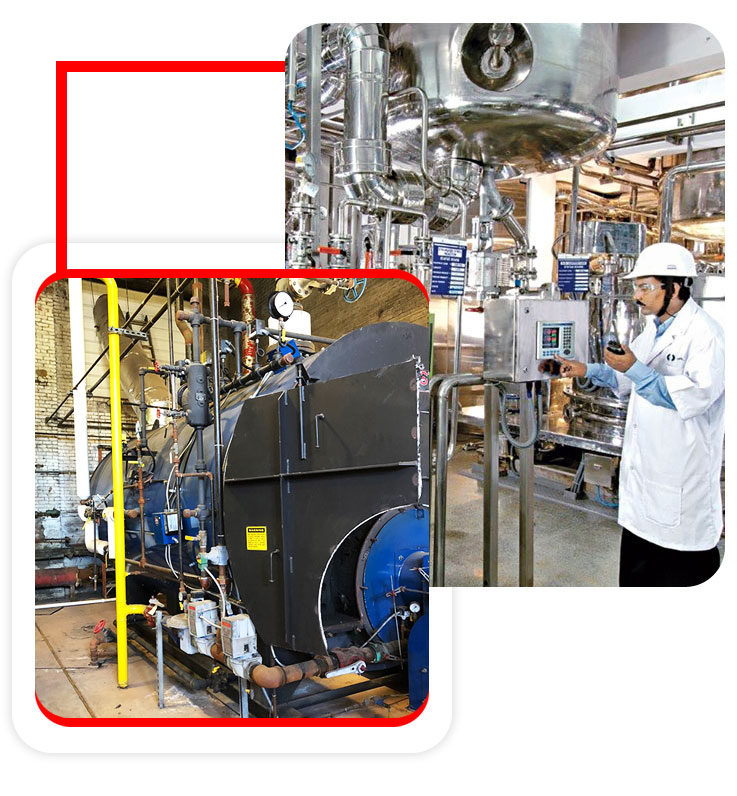

Maximize efficiency and reliability with our cutting-edge industrial heating systems. From Steam Boilers to Thermic Fluid Heaters, we deliver unmatched performance tailored to your industry needs. Trust our Hot Water Generators and Hot Air Generators for consistent output and energy savings

![]() Energy-Efficient |

Energy-Efficient | ![]() Durable Design |

Durable Design | ![]() Customizable Solutions

Customizable Solutions

Unlock peak performance with our Rotary Process Equipment, Static Process Equipment, and Specialized Plant Equipment. Built for durability and efficiency, our solutions are designed to optimize your industrial processes, reduce downtime, and enhance productivity.

![]() Custom Fabrication |

Custom Fabrication | ![]() High-Performance Design |

High-Performance Design | ![]() Low Maintenance

Low Maintenance

Our state-of-the-art products are built with cutting-edge technology to meet the demands of diverse industries. Our industrial towers ensure maximum efficiency in distillation and absorption processes. Boilers are designed for superior thermal performance, while our vessels and storage tanks provide exceptional durability and safety for handling critical materials. Our heating systems offer precise temperature control and energy-efficient operation, catering to industries requiring advanced thermal solutions.

With a strong global footprint across the USA, UAE, Saudi Arabia, Malaysia, Germany, and more, Ascent is the preferred partner for industries worldwide. Experience unmatched quality and innovation with Ascent!”

expertly crafted for unmatched performance and efficiency. As a trusted manufacturer, we deliver solutions that redefine industry standards. 🚀 Explore our product range and discover more

designed and manufactured for top-notch performance. 🌟 Discover the perfect cooling solution for your needs.

designed and manufactured to meet your industry’s toughest demands. 🚀 Explore our cutting-edge solutions today.

manufactured to deliver unmatched durability and performance. 🚀 Discover the perfect solution for your needs.

We manufacture, supply, and export a wide range of industrial equipment, including:

1. Industrial Towers (Distillation Towers, Absorption Towers, Cooling Towers)

2. Boilers (Industrial Steam Boilers, Hot Water Boilers)

Heating Systems (Thermic Fluid Heaters, Hot Water Generators)

3. Storage Tanks (Chemical Storage Tanks, Process Tanks)

4. Industrial Vessels (Mixing Vessels, Pressure Vessels)

Each product is designed for durability, efficiency, and exceptional performance.

We are based in Goregaon, Mumbai, India, and have been serving industries locally and internationally since 1996.

Absolutely! We export to major global markets, including:

USA, UAE, Saudi Arabia, Malaysia, Germany And several other countries, ensuring adherence to international standards.

Our products are widely used across industries such as:

1. Oil & Gas

2. Chemical Processing

3. Pharmaceuticals

4. Power Generation

5. Food & Beverage

6. Processing

7. Textiles

We cater to diverse industrial needs with precision-engineered solutions.

Our heating systems, including Thermic Fluid Heaters and Hot Water Boilers, are known for:

1. Precise temperature control

2. Energy efficiency

3. Robust construction

4. Long operational life

They are ideal for industries requiring consistent and efficient thermal solutions.

We offer Crossflow Cooling Towers, Counterflow Cooling Towers, and Modular Cooling Towers, engineered for maximum cooling efficiency and operational reliability.

Our industrial vessels and storage tanks are designed for:

1. High durability and corrosion resistance

2. Versatility for chemical, liquid, or material storage

3. Customizable sizes and specifications

4. We ensure safety and longevity in every product.

Our boilers are built with advanced technology to provide:

1. High thermal efficiency

2. Consistent steam generation

3. Durability under high-pressure conditions

4. Perfect for energy-intensive applications in various industries.

Yes, we provide tailored solutions to meet your unique industrial requirements, ensuring our products integrate seamlessly into your operations.

We use high-grade materials such as stainless steel, carbon steel, and alloys, ensuring strength, reliability, and resistance to harsh industrial environments.

We have over 25 years of experience delivering world-class industrial solutions, making us a trusted partner in the global market.

It’s simple! Click here to contact us or explore our detailed product pages to learn more about our offerings and find the perfect solution for your business needs.

Our reputation is built on:

1. A team of highly skilled engineers

2. Advanced manufacturing processes

3. Compliance with international quality standards

4. Commitment to customer satisfaction

5. We ensure every product we deliver exceeds expectations.

Yes, we offer exceptional after-sales support, including maintenance, servicing, and technical assistance, to ensure smooth and uninterrupted operations.

Yes, all our products are designed with energy efficiency in mind, helping industries reduce operational costs while maintaining peak performance.

ASCENT MACHINERIES & ENGG. SERVICES Shop No. 2, 1st Floor, Nalanda Shopping Center, Station Road, Goregaon West, Mumbai - 400062, Maharashtra, India

+919819063898

sales@ascentmes.com

© 2025 Ascentmes.com. All rights reserved. Designed by Vebiotic Web Solutions Marketing by Adinads