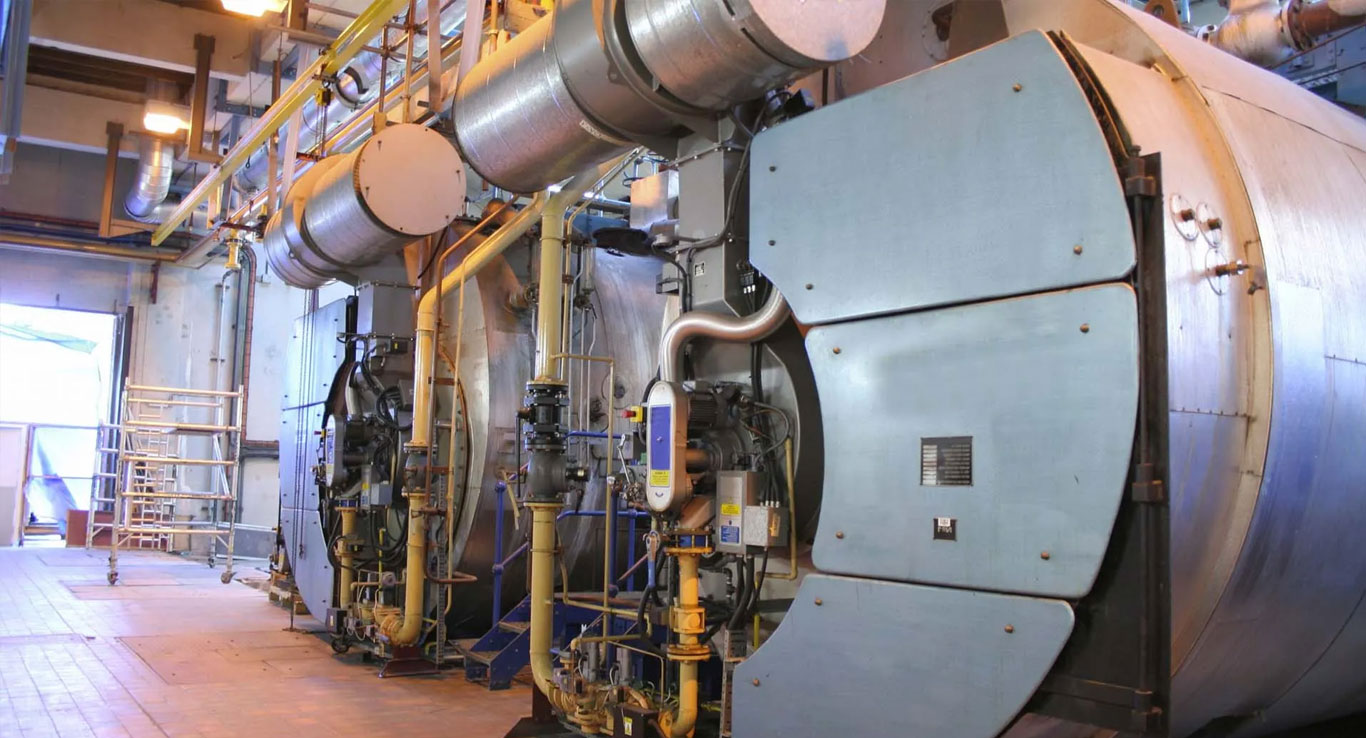

Preventing Boiler Overheating in Manufacturing Operations

Steam boilers play a crucial role in the processing operations of manufacturing industries. To ensure that the boiler system functions smoothly, plant managers must adhere to several guidelines and practices. While problems such as corrosion, carryover, and scaling may occur, overheating is a serious boiler issue that requires immediate attention. Overheating may lead to severe damage to the process plant and pose a risk to the operating personnel by increasing the likelihood of an explosion. Although modern boilers come equipped with safety fittings to lock the components before the boiler overheats, it is essential to be aware of the signs of boiler overheating to prevent it from occurring in the first place.

What is Boiler Overheating?

Boiler overheating can occur when the safety equipment fails to function properly, leading to potentially dangerous consequences. When hot water is prevented from circulating in the central heating system due to pump failure or blockage, steam boilers can overheat. In addition, failure of safety controls responsible for maintaining temperature, pressure, gas, and water supply can also cause the boiler to overheat, leading to hazardous conditions such as a “runaway boiler.”

When a boiler overheats, the internal components of the boiler are subjected to immense stress that can cause irreparable damage or, in extreme cases, result in a boiler explosion. Overheating can also cause the components of the boiler to melt, releasing toxic smoke into the surrounding area. Fortunately, modern steam boilers are equipped with automation control features that lock the units to prevent overheating and display an error message to alert plant managers to the issue.

Reasons for Boiler Overheating:

If the overheating of the boiler is not prevented or detected early on, it can pose a significant threat to the environment and the people nearby. Some common causes of boiler overheating are:

Limescale Build-up:

The accumulation of limescale on the heat exchangers restricts the water flow, leading to boiler overheating. The heat exchanger’s purpose is to heat the water before circulating it for combustion. The accumulation of limescale is also known as “kettling” as it produces a whistling sound similar to a boiling kettle.

Blockage in the System:

A blockage in the steam boiler system is characterized by unusual noises coming from the system. If a radiator is not heating correctly, it could be an indication of a blockage in the boiler system. A power flush process is usually performed to remove limescale, rust, and other impurities to enable the smooth circulation of hot water.

Faulty Pump:

The purpose of a pump is to circulate water in the steam boiler system. If the pump fails to operate, the hot water fails to leave the steam boiler system, leading to boiler overheating. Engineers usually repair pumps, but they may need to be replaced in some cases.

Faulty Thermistor:

The thermistor monitors the water temperature and adjusts it as per the demand. If the thermistor fails, the water temperature increases uncontrollably, leading to boiler overheating.

Precautions Required to Prevent Boiler Overheating

To avoid the damage caused by boiler overheating, it is advisable to take preventive measures. The following precautions can be taken to prevent boiler overheating:

- Magnetic filter installation: Fitting a magnetic filter to the heating system collects debris and rust before it builds up and forms a blockage. This build-up of debris is a common cause of various boiler issues that should be avoided.

- Scale reducer installation: Installing a scale reducer decreases the amount of limescale formation in hard water. Reduced limescale ensures that the steam boiler system is free of hindrances in water flow that may cause boiler overheating.

- Avoid introducing cool water into an overheated system: Do not supply the steam boiler with cool water when the system is overheated. It results in the boiler flashing into steam as it is introduced to the hot components of the steam boiler, causing a tremendous and immediate rise in pressure. It can lead to boiler explosion or rupture of components.

- Avoid constant flow of gases: Avoid constant flow of gases in the steam boiler as it causes a rapid increase of temperature and pressure, leading to a runaway boiler.

Repairs by experienced engineers: Reparations of steam boilers should only be conducted by experienced engineers. Inexperienced engineers can cause issues such as wiring errors, manual opening of gas valves, removing pressure relief valves while repairing boiler leakage and neglecting to fit them back, which can prevent the boiler system from facing excess pressure. This negligence can consequently lead to boiler overheating.

Conclusion

Preventing boiler overheating is crucial for ensuring the safety of the plant and the people working around it. By following necessary precautions such as fitting a magnetic filter, installing a scale reducer, and avoiding supplying cool water to an overheated system, boiler overheating can be prevented. However, in case of any issues, it is essential to seek help from experienced engineers who can provide effective solutions. At ASCENT MACHINERIES & ENGG. SERVICES, our team of skilled engineers has the expertise to diagnose and repair boiler issues, ensuring that your system runs smoothly and safely. Contact us today for reliable boiler maintenance and repair services.

For more information about our products and services, please visit our website at https://ascentmes.com