Home > Product Range > Industrial Cooling Tower

Ascent Machineries & Engineering Services Ltd., based in Goregaon, Mumbai, India, is a leading name in the design, manufacture, supply, and export of premium-quality industrial cooling towers. Our offerings include Cooling Towers by Types, Cooling Tower Spares, and Cooling Tower Repairs, all tailored to meet the specific needs of industries worldwide. Our solutions are focused on energy efficiency and cost-effectiveness, ensuring superior performance and operational savings for our clients.

Lightweight and corrosion resistant.

Clean energy solutions for industrial heating.

Affordable solutions for industries with alternative fuel availability.

Durable and economical cooling solutions.

Engineered for strength and efficiency.

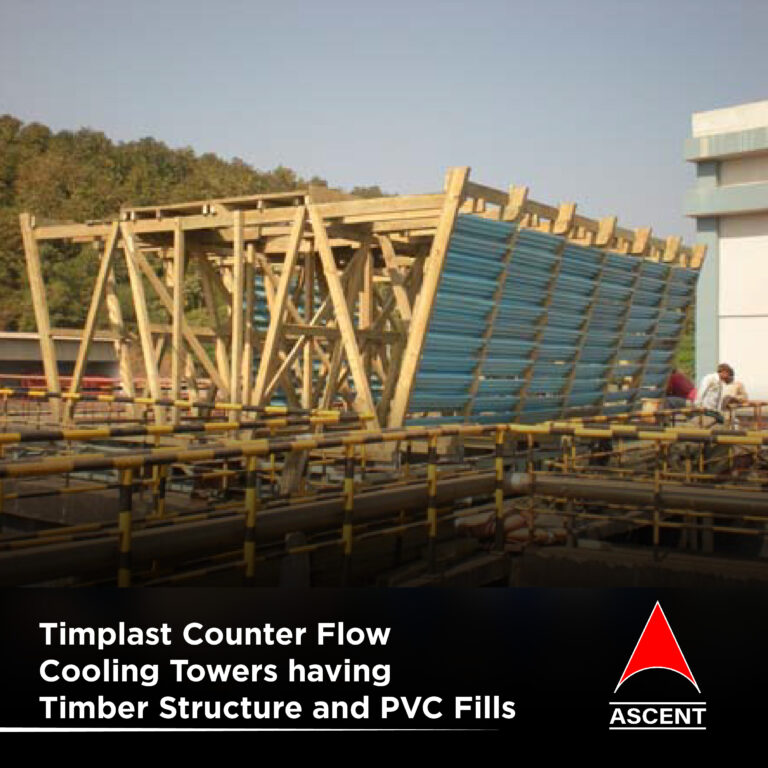

Timber structure with PVC fills for high performance.

FRP and Treated Timber Induced Draft Cooling Towers are advanced cooling systems designed to efficiently dissipate heat from industrial processes or HVAC systems.

Timber Natural Draft Cooling Towers are eco-friendly and efficient cooling systems designed to dissipate heat from industrial processes or HVAC systems using natural convection.

Built with treated timber for longevity. Incorporates induced draft technology for enhanced cooling efficiency.

Components designed for long-lasting performance.

Timber structure with PVC fills for high performance.

Restoring and enhancing timber cooling towers.

Upgrading from gear-driven to direct-driven systems.

Comprehensive inspections and upkeep.

01

Energy Efficiency

Reduces energy consumption with optimized heat transfer designs.

02

Cost Savings

Lowers operational and maintenance costs over time.

03

Eco-Friendly Designs

Features water-saving technologies and environmentally sustainable materials.

04

Versatility

Applicable across industries such as power, chemicals, HVAC, and manufacturing.

Our commitment to quality is evident in every product we deliver. All cooling towers and components are manufactured to meet ISO, ASME, and CE standards. Rigorous quality checks ensure performance, safety, and longevity. Despite this high standard of excellence, we maintain competitive pricing, offering our clients exceptional value.

We have supplied and exported industrial cooling towers and related products to the following countries and cities:

| Country | Cities |

| India | Mumbai, Pune, Chennai, Kolkata |

| UAE | Dubai, Abu Dhabi, Sharjah |

| USA | Houston, Los Angeles, Chicago |

| UK | London, Manchester, Birmingham |

| Germany | Berlin, Frankfurt, Munich |

| Australia | Sydney, Melbourne, Brisbane |

| South Africa | Johannesburg, Cape Town, Durban |

| Singapore | Singapore City |

We accept various payment methods, including bank transfers, credit cards, and letters of credit.

Yes, all our cooling towers and components are covered by a standard warranty, with extended warranties available upon request.

Delivery timelines vary based on the product type and destination, typically ranging from 4 to 6 weeks for standard orders.

Yes, our team provides comprehensive installation and commissioning services, including on-site technical assistance.

We provide annual maintenance contracts, periodic inspections, and emergency repair services to ensure optimal cooling tower performance.

Discover more about our industrial cooling tower solutions by downloading our detailed brochure. It includes:

Optimize your industrial cooling operations with Ascent Machineries’ advanced solutions. Contact us today to discuss your requirements and receive a customized proposal:

ASCENT MACHINERIES & ENGG. SERVICES Shop No. 2, 1st Floor, Nalanda Shopping Center, Station Road, Goregaon West, Mumbai - 400062, Maharashtra, India

+919819063898

sales@ascentmes.com

© 2025 Ascentmes.com. All rights reserved. Designed by Vebiotic Web Solutions Marketing by Adinads