Home > Product Range > Industrial Process Equipment

Ascent Machineries & Engineering Services Ltd., based in Goregaon, Mumbai, India, is a trusted name in the manufacturing, supply, and export of high-quality industrial process equipment. Our portfolio includes Rotary Process Equipment, Static Process Equipment, Specialised Plant Equipment, and Industrial Vessels and Storage Tanks. We are committed to delivering energy-efficient and cost-effective solutions tailored to the diverse needs of industries worldwide. Our products adhere to stringent international standards, ensuring durability, reliability, and performance.

For mixing and processing fluids.

Designed for precise and controlled chemical reactions.

Affordable solutions for industries with alternative fuel availability.

For uniform flake formation.

Agitators are essential mechanical devices used to mix, blend, or stir liquids, solids, or gases in various industrial processes.

A Venturi Scrubber is a high-efficiency air pollution control device designed to remove particulate matter and gaseous pollutants from industrial exhaust streams.

A Venturi Scrubber is a high-efficiency air pollution control device designed to remove particulate matter and gaseous pollutants from industrial exhaust streams.

Designed for continuous processing

Designed for precise and controlled chemical reactions.

Affordable solutions for industries with alternative fuel availability.

Chimney stacks and tall towers are types of vertical structures

Atmospheric fixed and floating roof storage tanks are types of containers

Designed for precise and controlled chemical reactions.

Hydrogenators or high-pressure autoclaves are specialized plant equipment

GMP reaction and distillation systems are specialized plant equipment used in the production of bulk drugs

Ribbon Blenders are versatile and robust mixing equipment designed for efficient and homogenous blending of powders, granules, and pastes.

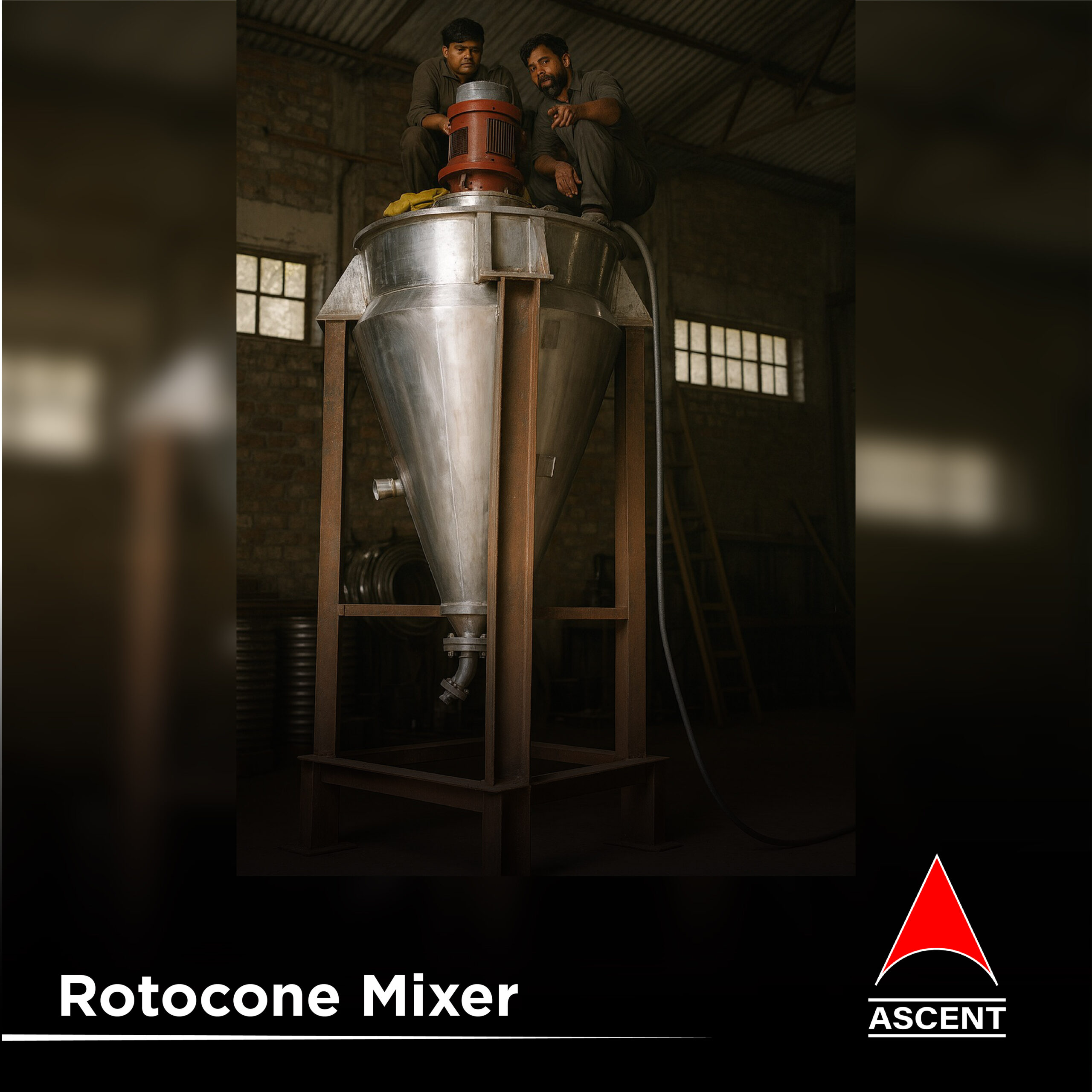

Rotocone Mixers are advanced industrial equipment designed for efficient mixing, drying, and homogenization of powders, granules, and semi-solid materials.

Industrial Dryers are robust and efficient equipment designed to remove moisture from materials in bulk, ensuring consistency, quality, and improved shelf life.

Industrial Filters are essential components in various industrial processes, designed to remove impurities, contaminants, and particulates from liquids, gases, or air.

01

Energy Efficiency

Incorporates advanced designs and technologies to reduce energy consumption.

02

Cost Savings

Minimizes operational costs through efficient heat transfer and low maintenance requirements.

03

Enhanced Productivity

Optimized designs improve process throughput and quality.

04

Technology Integration

Features control systems like PLC and SCADA for precise operation and monitoring.

At Ascent Machineries, we prioritize quality and affordability. Our products undergo rigorous quality checks to meet ISO, ASME, and CE standards. Despite our commitment to excellence, we offer competitive pricing to ensure value-driven solutions for our customers.

We have successfully supplied and exported industrial process equipment to the following countries and cities:

| Country | Cities |

| India | Mumbai, Pune, Chennai, Kolkata |

| UAE | Dubai, Abu Dhabi, Sharjah |

| USA | Houston, Los Angeles, Chicago |

| UK | London, Manchester, Birmingham |

| Germany | Berlin, Frankfurt, Munich |

| Australia | Sydney, Melbourne, Brisbane |

| South Africa | Johannesburg, Cape Town, Durban |

| Singapore | Singapore City |

We accept bank transfers, credit cards, and letters of credit for international transactions.

Yes, our products include a standard warranty. Extended warranties are available upon request.

Delivery timelines vary based on the product type and destination but typically range from 4 to 6 weeks for standard orders.

Yes, we provide comprehensive installation services and ongoing technical support.

We offer annual maintenance contracts, periodic inspections, and emergency repair services to ensure optimal performance.

For more details about our industrial process equipment, download our brochure. It includes:

Optimize your industrial cooling operations with Ascent Machineries’ advanced solutions. Contact us today to discuss your requirements and receive a customized proposal: