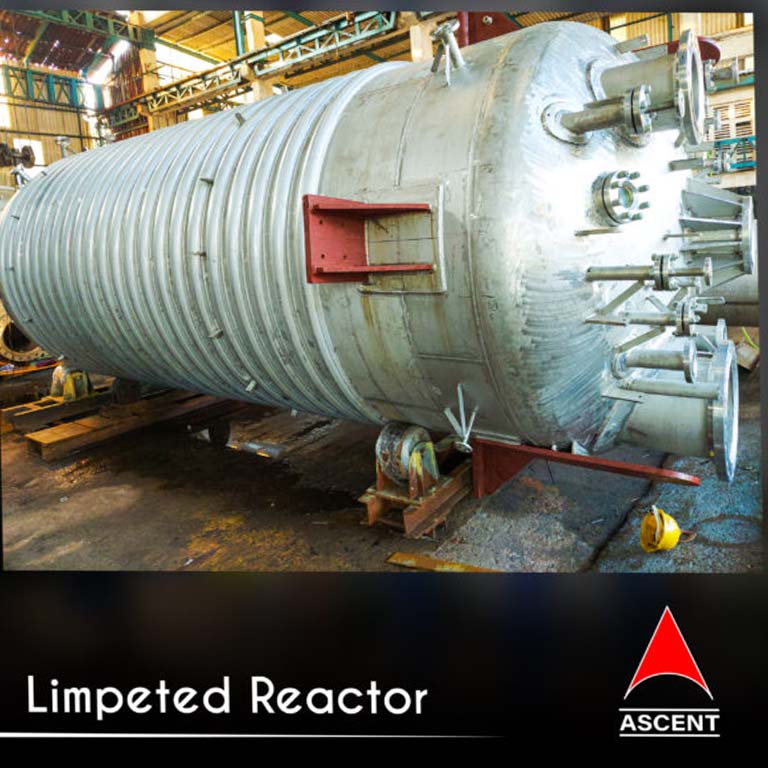

Home > Product Range >Industrial vessel storage tanks > Industrial Storage Tank and vessels > Limpet/Jacketed Reactors

Limpet and jacketed reactors are advanced industrial vessels designed for chemical reactions under controlled temperature and pressure conditions. Equipped with limpet coils or jackets for efficient thermal regulation, these reactors are indispensable in industries such as pharmaceuticals, chemicals, petrochemicals, and food processing.

Ascent Machineries & Engineering Services is a globally recognized manufacturer, supplier, and exporter of high-quality limpet and jacketed reactors. Adhering to international standards such as ASME and ISO, we provide cost-effective and reliable solutions tailored to the specific needs of our clients worldwide.

Limpet and jacketed reactors are engineered to meet stringent operational and safety requirements. Below are the critical technical aspects:

Below is a pricing table showcasing models, capacities, and approximate costs:

| Model | Capacity (Liters) | Material | Approx. Price (USD) |

| LJR-500 | 500 | Stainless Steel | 9,500 |

| LJR-1000 | 1,000 | Stainless Steel | 14,000 |

| LJR-5000 | 5,000 | Carbon Steel | 28,000 |

| LJR-10000 | 10,000 | Hastelloy | 65,000 |

Comparison with Alternatives:

Stainless steel reactors are a preferred choice for their corrosion resistance and durability. Carbon steel is a more economical option but less resistant to chemical reactions. Special alloys like Hastelloy offer the best performance for highly corrosive environments but come at a higher cost.

Limpet and jacketed reactors are equipped with several advanced features, making them suitable for a wide range of industrial applications:

Optimized temperature control through limpet coils or jackets.

Built to withstand extreme pressure and temperature variations.

Tailored to meet specific industrial needs.

Equipped with agitators for uniform reaction processes.

Features such as pressure relief valves and advanced monitoring systems.

Here is a detailed table outlining the technical specifications:

| Parameter | Details |

| Design Pressure | Up to 20 bar |

| Operating Temperature | -50°C to 300°C |

| Material Grades | SS304, SS316, Hastelloy, Carbon Steel |

| Volume Range | 100 liters to 20,000 liters |

| Thermal Control | Limpet Coils, External Jackets |

| Testing Standards | ASME Section VIII, ISO 9001 |

| Agitator Types | Anchor, Turbine, Propeller |

| Safety Features | Pressure Relief Valves, Rupture Discs |

Limpet and jacketed reactors are available in various configurations to meet unique industrial demands:

Efficient for basic thermal control.

enhanced insulation and temperature regulation.

Provides indirect heating or cooling for sensitive reactions.

Features integrated mixing systems for uniform reactions.

Cities: Mumbai, Delhi, Chennai, Bangalore, Dubai, Kuala Lumpur, and more.

Countries: India, UAE, Malaysia, South Africa, Kenya, UK, USA, Australia, and Vietnam.

We serve a diverse clientele across various industries. Highlights include:

We use materials such as SS304, SS316, carbon steel, and special alloys to cater to various industrial needs.

Yes, we offer fully customizable designs based on specific operational requirements.

All our reactors comply with ASME, ISO, and other international standards, ensuring top-notch quality and safety.

Looking for high-performance limpet and jacketed reactors? Contact Ascent Machineries & Engineering Services today! With our global expertise and innovative solutions, we deliver reliable equipment tailored to your needs. Request a Quote Now!

ASCENT MACHINERIES & ENGG. SERVICES Shop No. 2, 1st Floor, Nalanda Shopping Center, Station Road, Goregaon West, Mumbai - 400062, Maharashtra, India

+919819063898

sales@ascentmes.com

© 2025 Ascentmes.com. All rights reserved. Designed by Vebiotic Web Solutions Marketing by Adinads