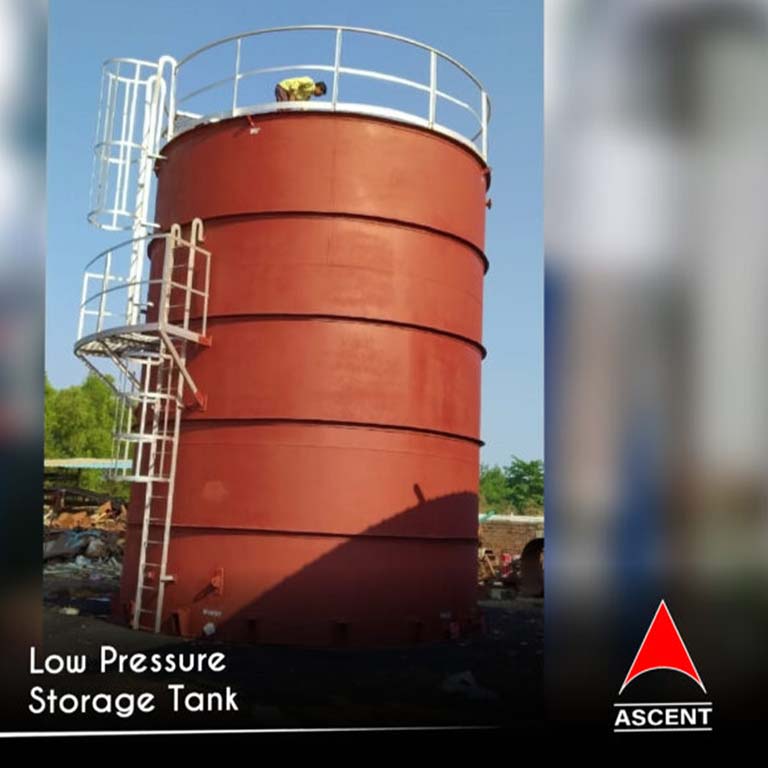

Home > Product Range > Industrial Process Equipment > Static Process Equipments > Low Pressure Storage Tank

Low Pressure Storage Tanks are specialized storage vessels designed to safely store liquids and gases at pressures slightly above atmospheric levels. Ideal for industries such as oil and gas, chemicals, pharmaceuticals, and food processing, these tanks are engineered to provide robust performance while minimizing risks associated with pressure variations. Their advanced sealing mechanisms, energy efficiency, and durability make them a preferred choice for diverse industrial applications.

Ascent Machineries & Engineering Services Ltd., based in Goregaon, Mumbai, India, is a renowned manufacturer, supplier, and exporter of premium-quality low-pressure storage tanks. With a global presence in over 80 countries, we deliver innovative and customized solutions that adhere to international standards, ensuring operational safety, cost-effectiveness, and environmental compliance.

Low-pressure storage tanks are designed to handle fluids and gases under controlled pressure and temperature conditions, ensuring safety and efficiency.

| Model | Capacity (Liters) | Material | Price (₹) |

|---|---|---|---|

| Compact Storage Tank | 1,000–10,000 | Carbon Steel | 4,50,000 |

| Standard Storage Tank | 50,000–100,000 | SS304 | 15,00,000 |

| Industrial Storage Tank | 250,000–500,000 | SS316 | 50,00,000 |

Market Comparison:

Built to withstand temperature and pressure variations.

Advanced sealing mechanisms ensure safety and minimize product loss.

High-quality materials and coatings enhance durability in corrosive environments.

Tailored to meet specific industrial requirements.

Complies with environmental standards for emissions.

Available in various sizes to accommodate diverse storage needs.

| Parameter | Details |

| Capacity Range | 1,000–500,000 liters |

| Pressure Range | Up to 10 bar |

| Material Options | Carbon Steel, SS304, SS316 |

| Operating Temp | -20°C to 120°C |

| Sealing Mechanism | PTFE, Viton Gaskets |

| Coatings | Anti-Corrosive, UV-Resistant |

| Country of Origin | India |

Space-saving design for efficient storage in compact areas.

Suitable for large-capacity storage and transportation.

Equipped with thermal insulation for temperature-sensitive applications.

Enhanced safety for hazardous material storage.

Cities: Mumbai, Delhi, Chennai, Bangalore, Dubai, Kuala Lumpur, and more.

Countries: India, UAE, Malaysia, South Africa, Kenya, UK, USA, Australia, and Vietnam.

They offer cost-effective storage solutions for large volumes of liquids and gases under controlled conditions.

Yes, materials like SS316 and specialized coatings make them suitable for corrosive environments.

Delivery timelines range from 6 to 10 weeks, depending on specifications.

Ensure safe and efficient storage with Ascent Machineries & Engineering Services Ltd.‘s premium low-pressure storage tanks. Contact us today for customized solutions tailored to your industrial needs.

ASCENT MACHINERIES & ENGG. SERVICES Shop No. 2, 1st Floor, Nalanda Shopping Center, Station Road, Goregaon West, Mumbai - 400062, Maharashtra, India

+919819063898

sales@ascentmes.com

© 2025 Ascentmes.com. All rights reserved. Designed by Vebiotic Web Solutions Marketing by Adinads