Home > Product Range > Industrial Process Equipment > Specialised Plant Equipments > Rotocone Mixers

Rotocone Mixers are advanced industrial equipment designed for efficient mixing, drying, and homogenization of powders, granules, and semi-solid materials. Combining gentle tumbling action with vacuum drying capabilities, these mixers ensure uniform mixing while preserving material integrity. Ideal for applications requiring controlled mixing and drying, rotocone mixers are widely used in pharmaceuticals, chemicals, food processing, and cosmetics industries.

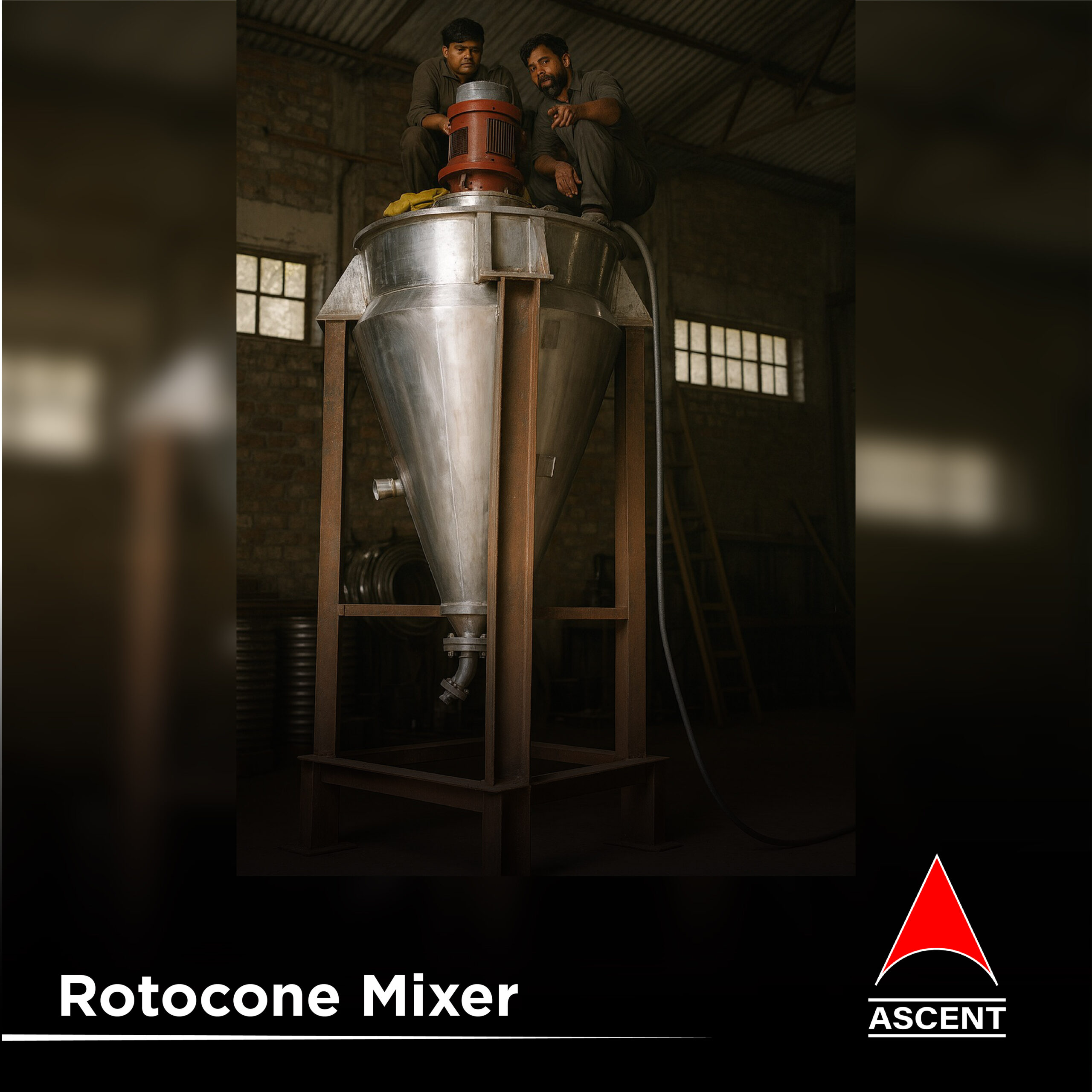

Ascent Machineries & Engineering Services Ltd., based in Goregaon, Mumbai, India, is a globally recognized manufacturer, supplier, and exporter of premium rotocone mixers. With a presence in over 80 countries, we provide innovative solutions that adhere to international quality standards, ensuring superior performance, cost-effectiveness, and customer satisfaction.

Rotocone mixers are designed for precision mixing and drying processes, providing superior performance and operational safety.

| Molde |

Capacity (Liters) | Material | Price (₹) |

| Compact Rotocone Mixer | 5–100 | SS304 | 3,50,000 |

| Standard Rotocone Mixer | 500–1,000 | SS316 | 10,00,000 |

| Industrial Rotocone Mixer | 5,000–10,000 | Hastelloy | 40,00,000 |

Market Comparison:

Ensures uniform blending without degrading materials.

Facilitates moisture removal for sensitive materials.

High-quality materials provide durability in harsh environments.

Tailored solutions for specific industrial needs.

Optimized designs reduce power consumption.

Smooth surfaces and easy cleaning ensure compliance with GMP standards.

| Parameter | Details |

| Capacity | 5–10,000 liters |

| Vacuum Range | Up to -760 mmHg |

| Temperature Range | Ambient to 150°C |

| Material Options | SS304, SS316, Hastelloy |

| Mixing Time | 10–60 minutes |

| Sealing Mechanism | FDA-approved PTFE, Viton |

| Automation Features | PLC and SCADA integration |

| Country of Origin | India |

Designed for general-purpose mixing and drying.

Enhanced drying capabilities for moisture-sensitive materials.

Suitable for large-scale industrial production.

For temperature-controlled mixing and drying.

Cities: Mumbai, Delhi, Chennai, Bangalore, Dubai, Kuala Lumpur, and more.

Countries: India, UAE, Malaysia, South Africa, Kenya, UK, USA, Australia, and Vietnam.

How Did We Improve Drying Efficiency for a Pharmaceutical Company?

How Did We Enhance Mixing Uniformity for a Chemical Producer?

Yes, they are suitable for both wet and dry mixing applications.

Absolutely, we provide tailored designs to meet specific industrial requirements.

Delivery timelines range from 6 to 12 weeks, depending on specifications.

Optimize your mixing and drying processes with Ascent Machineries & Engineering Services Ltd.‘s high-performance rotocone mixers. Contact us today for customized solutions tailored to your industrial needs.